Integrated Multi-Pollutant Synergistic Ultra-Low Emission System with Ceramic Catalysts for High-Fluoride Industries

Integrated Multi-Pollutant Synergistic Ultra-Low Emission System with Ceramic Catalysts for High-Fluoride Industries

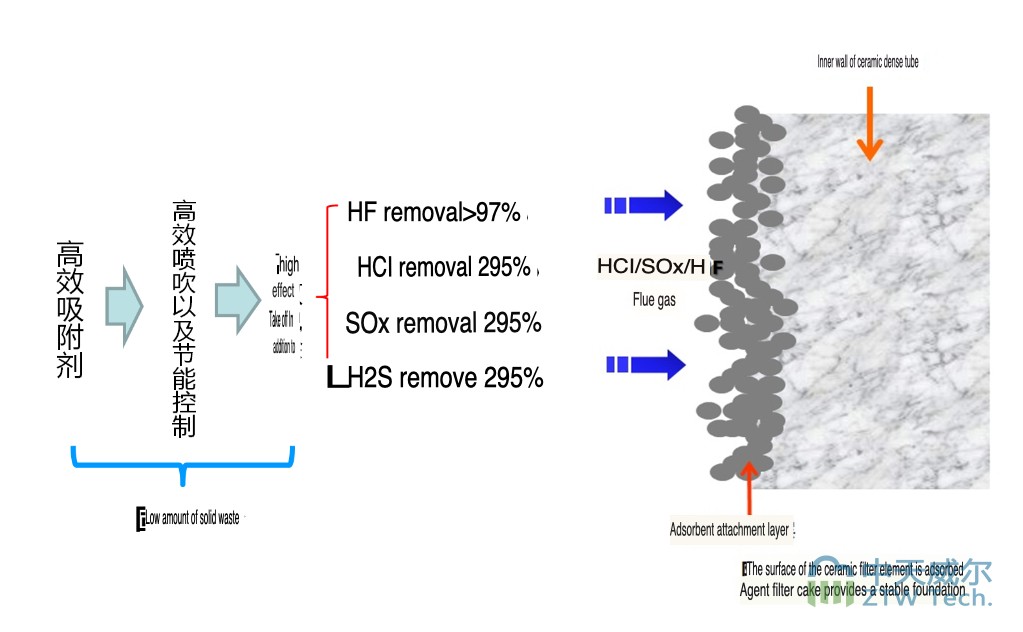

This advanced system specializes in treating flue gas containing high-concentration fluorides through a proprietary process:

Conditioning Adsorbent + Ceramic Tube Reactor

Key Process Details:

- Pre-treatment Stage

- The conditioning adsorbent chemically modifies fluoride compounds to enhance reactivity

- Adjusts gas composition for optimal ceramic catalyst performance

- Core Reaction Stage

- Ceramic tube reactor simultaneously achieves:

• Fluoride removal efficiency >98%

• SO₂/NOx co-removal

• Particulate filtration - Operates at 180-300°C without secondary heating

- Ceramic tube reactor simultaneously achieves:

- Emission Performance

- Outlet fluoride concentration <1mg/Nm³

- Particulate matter <5mg/Nm³

- System pressure drop <800Pa

Technical Advantages:

✓ Corrosion-resistant ceramic structure withstands HF attack

✓ Integrated purification replaces traditional multi-stage scrubbers

✓ Zero wastewater generation - dry process eliminates slurry disposal

✓ Automated operation with real-time fluoride monitoring

Suggested Application Fields:

• Aluminum electrolysis • Phosphate fertilizer • Lithium battery recycling